For a fresh newcomer of textile business, you may get lost when you want to choose the fabric for your product. As there are so many kinds of materials in the market, here would give brief guide about the fabrics that normally used.

Generally speaking, there are several types of fabrics:

1, polyester

2, nylon

3, non-woven

4, woven

5, canvas

6, Cordura

What is polyester material?

The most used material in bag industry, but if you just inform about the polyester fabric then the price can be varied a lot. As polyester can be divided into many different types based on Denier of yarn used for woven, below are some used most:

1, 210D (normally for shopping bag or lining)

2, 420D

3, 600D (most used fabric)

4, 900D, 1000D (used for outdoor bags or bags with heavy capacity request)

5, 1680D (used for outdoor bags or bags with heavy capacity request)

Fabric with bigger Denier number with thicker yarn, thus has higher durance and weight loading capacity.

Also in some cases use Tex orStaple to identify the yarn, but in bag business Denier is commonly accepted.

The recycle material called RPET is recycled polyester, part of polyester category, but made by recycled PET, more eco-friendly and more sustainable. It is the material getting rising attention in the market.

What is nylon material?

Nylon material is the second choice of the fabric, but due to high material cost, not every customer can accept it. Same as polyester, nylon also can be divided into different types based on Denier count.

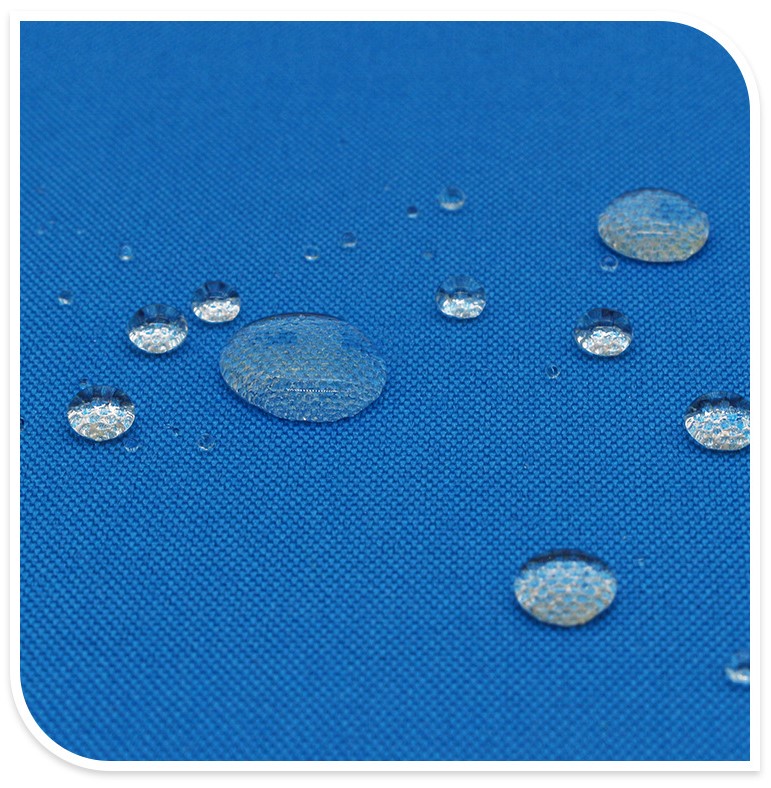

Both polyester and nylon fabrics need to do some coating on surface to have different function or result. The outside surface of fabric can have water repellent or waterproof coating, water repellent coating, can have water resistant result for short time contact, this coating has been used for most of fabric surface. For waterproof surface, the coating is bit different from water repellent, means fabric can hold the water without any penetration of humidity. In order to have 100% waterproof finished product, all parts of the product need to have waterproof process, like waterproof zipper and instead of sewing up will use heat seal or sew with back side heat seal.

Back side of the fabric can have different kind of coating, including PVC, PU, TPU, TPE etc. PVC and PU are most used. Compared to PVC, PU is thinner and softer touching result, used for bags that request light weight or packable function. PVC used for bags requested rigid and stiff shaping result, like laptop bag, school bag. For 100% waterproof bag like dry bag or swimming buoy, specially use thick PVC or TPU coating, so the hot seal process can be applied.

What is non-woven and woven material?

These two materials are like perfect opposites, raw material is the same Polypropylene (PP), but the production method is different, caused different fabric result. For bag production, both material needs to have surface lamination to have better resistance and water repellent/waterproof function.

With different weights per square meter, material show different thickness from 40gsm to 200gsm or higher. These two materials widely used for shopping bag, carry bag or insulated cooler bag with lower price request, big demand in promotional event.

What is canvas material?

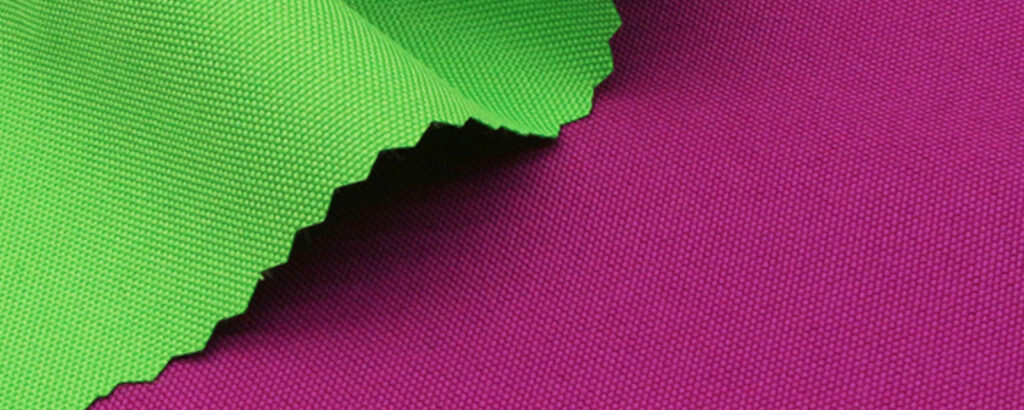

Canvas is a general calling name, based on the raw material composition, can be in three types: 100% cotton canvas, 100% polyester canvas and poly-cotton canvas (the percentage of two materials can be adjusted as per request, like 65% polyester and 35% cotton or 50%-50%).

Canvas divided based on weight per square yard, but calculated by ounce/oz, from 4oz-20oz or higher. Canvas as per the production request can do waxing process to have stiff and water repellent function.

What is Cordura material?

Cordura originally was a product brand under Dupont, known for their extreme durability, even used for the products of U.S. military. Timing passing by, more and more companies have learned this technology and able to produce this fabric with same or similar quality.

Cordura based on the raw material can be divided into polyester Cordura and nylon Cordura. And same as nylon and polyester fabric, can be many different types of fabrics due to different denier yarn and coating methods made.

Cordura due to its high cost, only used for high end products or has specific requests about the weight capacity like tactical bags.

We hope by now, you can have a rough picture about the main materials that used for bag production. Cien Good can give good guidance if needed during the process of customization or choosing the product to joint in as our distributor.